As a highly efficient grading equipment, air classifier has made remarkable progress in technology in recent years. In this article, we will briefly analyze the technical development status of air classifier.

Current status of technical development of air classifier

High classification accuracy

— Micron and nanometre classification: Modern air classifier can achieve high-precision classification at the micron or even nanometre level. By optimizing the airflow field and classifying wheel design, air classifier can meet the needs of high-end industries, such as medicine and electronic industries.

— Wide particle size distribution: Through multi-stage series or parallel design, a wider particle size range can be achieved to improve the uniformity and consistency of the product.

Intelligent control

–Automation control system: Introduce PLC (Programmable Logic Controller) and DCS (Distributed Control System) to realize automation control of the grading process and improve production efficiency and stability.

— Online monitoring and feedback: The sensor monitors the particle size, concentration,etc. in real time, and it can provide feedback to adjust the velocity of air flow and the speed of classifying wheel to ensure classification accuracy.

Energy saving and environmental protection

— Low energy consumption design: By optimizing air flow channel and the structure of classifying wheel, energy consumption is reduced and operating cost is reduced.

— Dust recovery technology: High-efficiency dust removal equipment (such as: bag dust collector and cyclone dust collector) is used to reduce dust emissions, to meet the requirements for environmental protection.

Multi-function

— One machine with multiple uses: Modern air classifier can not only perform classification, but also achieve multiple functions, such as drying, grinding, and surface modification, to meet various process requirements.

— Modular design: Through modular design, users can flexibly combine equipment with different functions according to their needs to improve the applicability of the equipment.

With the continuous advancement of industrial technology and the continuous updating of market demand, air classifier technology will be further improved. Moreover, the application areas of air classifier will be further expanded, e.g.: 3D printing materials industry and aerospace materials industry, thereby promoting industrial upgrading and technological progress in related industries.

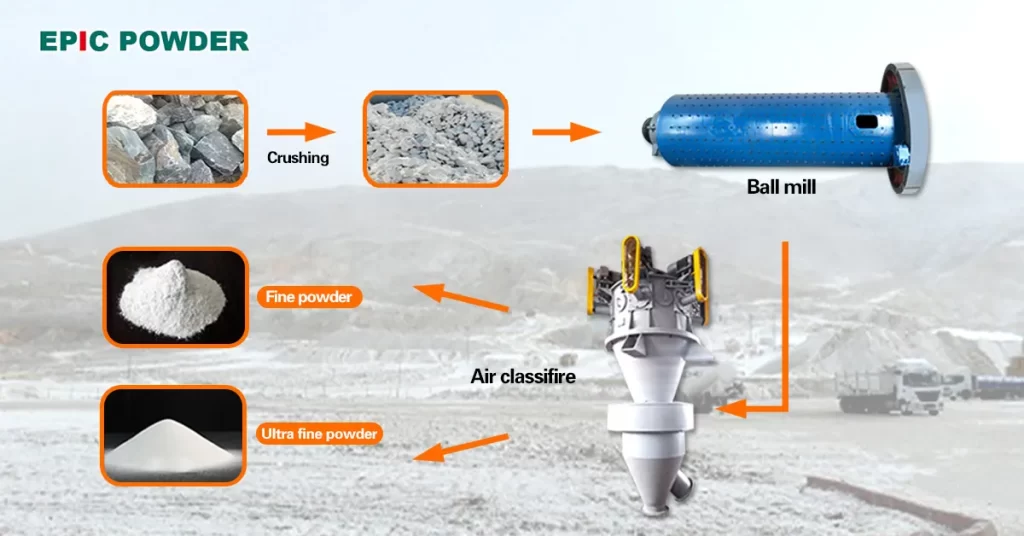

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Our products include: air classifier mill, ball mill, jet mill, roller mill, various air classifiers, powder coating and modification equipment and related auxiliary equipment. Among them, air classifier includes five types: HTS, ITC, MBS, CTC and TDC. Our air classifiers are designed under the guidance of German consultant, with excellent performance, stable quality and good consumer feedback.

In the field of powder processing equipment, we have rich production experience and technical accumulation, and we can provide customers with one-stop solutions from equipment selection, solution design to installation and commissioning, and after-sales service.

If you have relevant demands for air classifier or other powder processing equipment, or want to know more details, please feel free to contact our staff directly, we are always here for you.