Introduction

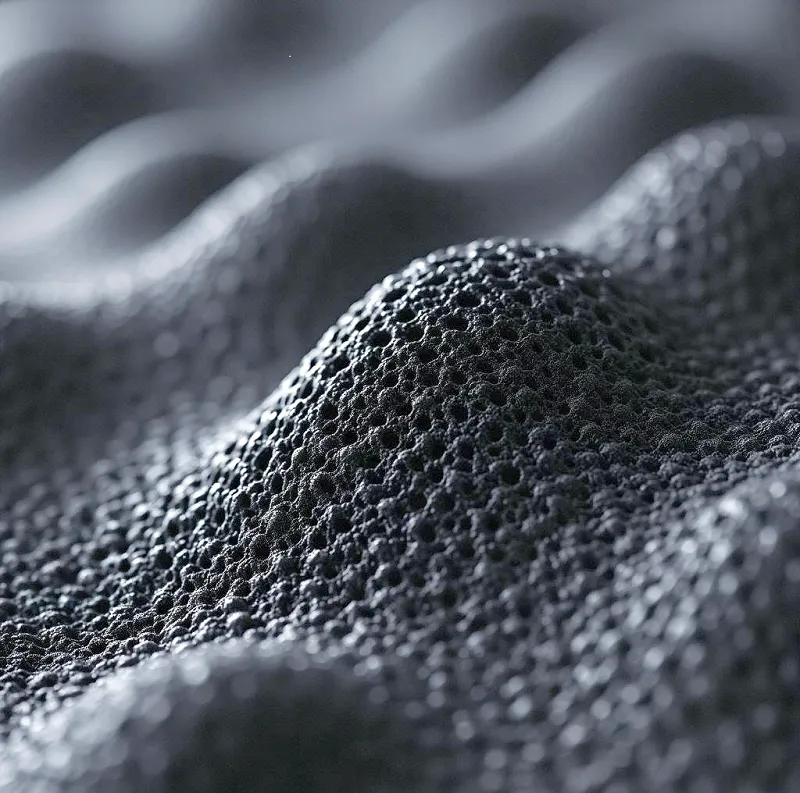

Porous carbon materials: the “skeleton battle” of silicon-carbon anodes

In the pursuit of higher energy density for lithium-ion batteries, silicon-carbon (Si/C) anodes are regarded as a key material to replace traditional graphite. However, silicon particles experience volume expansion of up to 300% during charge/discharge cycles, and this makes them highly dependent on the support of a porous carbon matrix. Among the three major carbon source routes—biomass, phenolic resin, and coal-based, which one will ultimately dominate as the preferred choice for silicon-carbon anodes? This battle over performance, cost, and sustainability is reshaping the industry landscape.

Technical competition among the three major carbon sources

1. Biomass Carbon: A Green Path Endowed by Nature

Core advantages

◆ Natural porous structure: Biomass itself has abundant pores (for example, the specific surface area of coconut shell carbon can reach 1000-2000 m²/g), which reduces the difficulty of subsequent activation.

◆ Low cost and sustainability: The raw materials have a wide range of sources, and the cost per ton can be as low as 20,000-50,000 yuan (only 1/3 of that of phenolic resin).

◆ Abundant surface functional groups: Oxygen/nitrogen-containing groups can enhance the bonding force at the silicon-carbon interface.

Technical bottlenecks

● Poor consistency: The composition of biomass varies significantly between different batches, which affects the stability of battery performance.

● Difficulty in impurity control: Metal ions (K⁺, Ca²⁺) require strict acid washing; otherwise, they will accelerate the decomposition of the electrolyte.

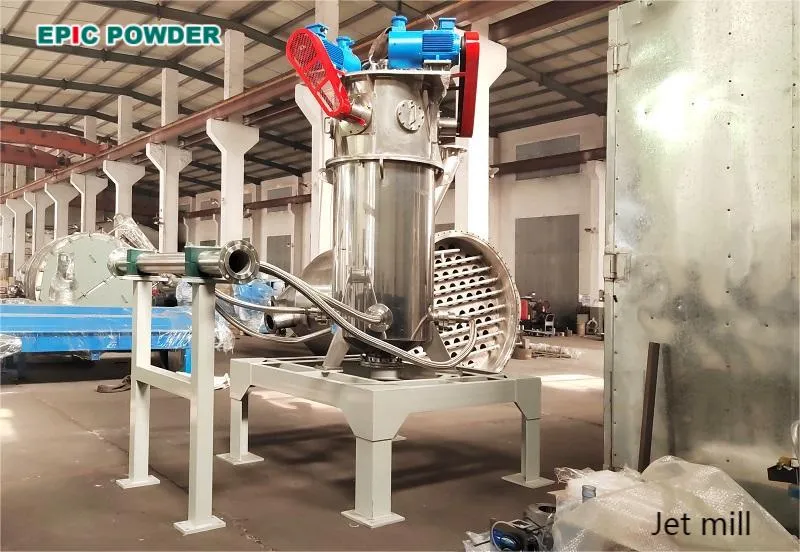

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment. Our products include powder grinding equipment, classification equipment, surface coating equipment, and related auxiliary equipment.

The jet mill and classifier produced by our company are important tools for solving the consistency issue of biomass carbon. Through ultra-fine grinding achieved by high-speed airflow impact and particle self-collision, metal contamination is avoided; furthermore, combined with precision classification technology, the particle size distribution (D50, D97) of carbon precursors can be accurately controlled, ensuring that each batch of raw materials has highly consistent physical properties. This lays a solid foundation for the stability of subsequent processes and the uniformity of the final porous carbon material performance, directly helping to overcome the industry pain point of “poor consistency”.

2. Phenolic Resin: A high-end choice prioritizing performance

Process characteristics: Precise regulation of pores (pore size adjustable from 2 to 50 nm) via polymerization-carbonization-activation.

Irreplaceability

◆ Precise structural controllability: Suitable for preparing gradient pores (macropores buffer expansion + mesopores promote ion transport), with an initial efficiency of over 90%.

◆ High purity and no impurities: The ash content after carbonization is less than 0.1%, which is far superior to that of biomass (usually more than 1%).

Major drawback

● High cost: Raw materials rely on petrochemicals, and the cost per ton is approximately 150,000-200,000 yuan;

● Environmental protection pressure: Formaldehyde is released during the production process, requiring supporting tail gas treatment equipment.

The performance advantages of phenolic resin-based porous carbon largely depend on the morphology of its carbonization precursor. By subjecting the polymerized phenolic resin prepolymer to ultra-fine grinding and precise classification, microspheres with better sphericity and more uniform particle size can be obtained. After carbonization, such microspheres can form porous carbon with a more regular structure and a more concentrated pore size distribution, significantly enhancing its conductivity and buffering effect when used as a carrier for silicon-based materials.

The classifier from Epic Powder is precisely the ideal choice for achieving efficient preparation and accurate classification of resin microspheres, helping to tap the maximum performance potential of the phenolic resin route. Epic Powder has 6 types of classifiers: HTS, ITC, TDC, TTS, MBS and CTC. They can satisfy different particle size requirements for different raw materials. If you want to know more details or have any related questions, please feel free to contact EPIC POWDER.

3. Coal-based Carbon: The dark horse breaking through with cost advantage

Raw material innovation: Hard carbon/soft carbon is prepared by modifying pitch, coking coal, etc.

Breakthrough advantage

◆ Cost reduction: the cost per ton can be reduced to 10,000-30,000 yuan, suitable for large-scale manufacturing;

◆ Graphitization compatibility: Some coal-based carbons can be directly used in existing graphite anode production lines.

Technical challenges

● Insufficient porosity: The specific surface area of traditional coal-based carbon is usually less than 500 m²/g, thus requiring strong oxidation activation.

● Sulfur/nitrogen residues: Affect the cycle life of batteries (e.g: sulfur causes instability of the SEI film).

Future Trends

High-end market: Phenolic resin carbon remains dominant

Suitable for scenarios sensitive to performance such as high-nickel ternary batteries, but it is necessary to reduce costs through monomer modification (e.g: boron doping).

Mainstream for power batteries: biomass-coal-based composite carbon

Biomass provides a porous structure, while coal-based carbon fills the framework to reduce costs; mixed carbon sources may become a compromise solution.

Ultimate black technology: Artificial directional synthesis of carbon

Molecular-level designed carbon, similar to MOFs (metal-organic frameworks), can balance structural accuracy and cost (laboratory stage).

Conclusion

There is no “perfect answer”—only “the optimal solution.”

The material competition for porous carbon is essentially a three-way balance between performance, cost, and sustainability. In the short term:

• High-end battery cells still rely on phenolic resin carbon;

• Power batteries will lean toward biomass/coal-based hybrid routes;

• Disruptive technologies (such as AI-assisted carbon structure design) may rewrite the rules of the game.

As the penetration rate of silicon-carbon anodes exceeds 10% (predicted for 2025), the winner of this material competition may determine the industrial landscape of next-generation batteries.