Introduction

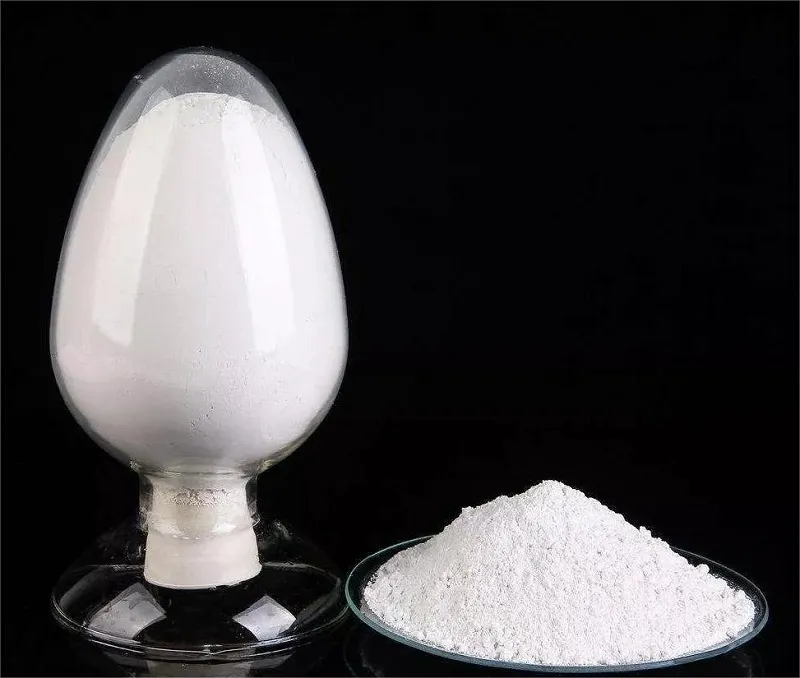

Silica is an artificially synthesized amorphous silicon dioxide (SiO₂) powder, with chemical formula SiO₂·nH₂O. It is an important functional material, widely used in fields of rubber, coatings, pharmaceuticals, etc. The performance of silica is closely related to key parameters such as particle size distribution (PSD) and specific surface area (BET), making efficient classification technology critical for optimizing its industrial applications. Air classifier produced by Qingdao Epic Powder Machinery Co., Ltd. can achieve accurate classification of silica without destroying the particle structure, thereby improving the uniformity and application performance of the product.

Advantages of air classifier for classifying silica

Air classifier is an equipment that uses multiple forces such as centrifugal force, inertial force, gravity, etc. to separate particles of different sizes. Its advantages are mainly reflected in:

– High classification accuracy

It can accurately separate silica particles of different particle sizes to obtain products with narrow particle size distribution and good uniformity.

– High production efficiency

By utilizing high-speed airflow, a large amount of silica can be quickly graded, improving production efficiency and meeting the needs of industrial production.

– Good environmental performance

The entire grading process is carried out in a closed system, avoiding dust leakage and pollution, and meeting environmental protection requirements.

– Easy to operate

It has a high degree of automation and is easy to operate. With setting relevant parameters, the equipment can run automatically, reducing the workload of manual operation.

Classification effect of air classifier on silica

① Precise particle size control

Ordinary silica (D50: 10 – 50 μm) → Fine powder with D97 < 10 μm can be separated, and even ultra-fine grade with D50: 1 – 5 μm can be obtained.

Nanoscale silica aggregates → Effectively break up aggregates and separate particles between 100 nanometers and 1 micron.

② Optimization of specific surface area

The specific surface area of unclassified silica may fluctuate significantly (e.g., 150 – 300 m²/g), while after classification:

Coarse particle part (specific surface area ↓, reinforcement reduced, suitable for ordinary fillers).

Fine particle part (specific surface area↑, suitable for high-end rubber and coatings).

③ Improvement in product consistency

After classification, the particle size distribution span (Span value) can be significantly reduced. For example:

Before classification: Span (D90-D10)/D50 ≈ 2.5 (wide distribution). After classification: Span < 1.5 (narrow distribution).

Actual application cases from Epic Powder

Case 1: One of our customers requires classification of silica for tires, to improve reinforcement and reduce rolling resistance of tires.

Our solution: By adopting multi-stage air classification, our customer obtained fine powder with D50: 5~10μm, the specific surface area increased by 15%, and the wear resistance of tire was improved.

Case 2: Another customer wants to prepare pharmaceutical-grade silica, with D90<10μm, and it should meet the pharmacopoeia standards.

Our solution: High-precision air classification + surface modification.

Air classifier can accurately classify silica into different particle sizes to meet the strict requirements of different application fields. In the future, with the further development of classifying technology, the application of air classifier in silica will be further expanded.

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment with many years of production experience and technical accumulation. Our products include: powder grinding equipment, classifying equipment, modification equipment and related auxiliary equipment. Air classifier is our main classification equipment, designed by our engineers under the guidance of our German consultant, and it includes five types: HTS, ITC, CTC, MBS and TDC. They are with excellent performance and competitive price, and widely praised by consumers. Our air classifier is very suitable for the classification of silica.

If you are purchasing air classifier or other powder processing equipment, please contact Epic Powder, and we’ll provide you a one-stop solution from equipment selection, solution design to installation and commissioning, and after-sales service.

Contact us, and let our professional equipment make your powder processing more efficient and intelligent!