Introduction

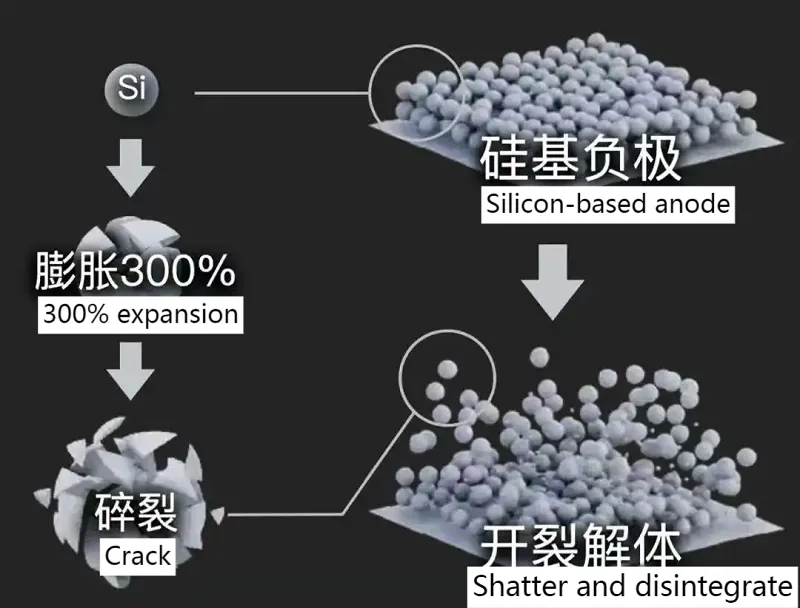

As the new generation of negative electrode materials for lithium-ion batteries, silicon-carbon composites have become the key to breaking through the bottleneck of energy density. This is because that their theoretical specific capacity is far higher than that of traditional graphite (up to 4200 mAh/g). Evenly dispersing nano-silicon particles to form a silicon-carbon composite material can alleviate problems of particle pulverization and structural collapse caused by the volume expansion of silicon materials, and it is the mainstream strategy to improve cycle stability. In the preparation process of this precision material, air classification technology has become a key link in ensuring material performance and large-scale production due to its unique advantages.

Working principle of air classifier

Air classifier achieves the separation of particles of different sizes based on the balance of inertial force, centrifugal force, and gravity acting on particles in the airflow. The core components include:

①Classifying wheel: The high-speed rotation generates centrifugal force, causing the coarse particles to be thrown outward and discharged, and the fine particles pass through the classifying wheel with the air flow and enter the collection system.

② Dispersion system: break up agglomerated particles through airflow or mechanical means to ensure that individual particles are classified independently.

③ Control system: Accurately adjust parameters such as velocity and classifying wheel speed to achieve narrow particle size distribution control.

The advantages of air classifier in the preparation of silicon-carbon anode

☆High-precision granularity control: the key to breaking through performance bottlenecks

· Narrow distribution ensures uniformity:

By adjusting parameters, such as: the rotor speed, air volume and velocity, D97 < 1μm precision cutting can be achieved to obtain composite powder with extremely narrow particle size distribution (PSD) (Span value <0.8).

Narrow PSD directly determines:

✅ Uniform dispersion of silicon particles in carbon matrix

✅ Consistency of electrode coating thickness

✅ Uniformity of stress distribution during charging and discharging (alleviating local rupture)

· Remove harmful components

Ultra-fine powder (<1μm): Efficient separation and discharge to prevent it from increasing the specific surface area and aggravating side reactions (such as excessive thickness of the SEI film), and improve the first coulomb efficiency (increase by 3-5%).

Coarse particles (>30μm): Accurately intercept to prevent electrode cracks caused by volume expansion during circulation.

☆ Dry classification: protecting the intrinsic properties of materials

Completely avoid the solvent residue, surface oxidation (especially sensitive to silicon) and subsequent tedious drying steps that may be caused by wet classification (such as water screening, hydrocyclone), and maintain the intrinsic properties of the material. This is very important for silicon-carbon materials that are sensitive to moisture and require strict control of the surface chemical state.

Application case

A lithium battery material enterprise customer used the HTS air classifier produced by Qingdao Epic Powder Machinery Co., Ltd. to control the particle size of silicon-carbon anode material at D50: 10±1μm, and the battery’s first charge and discharge efficiency was increased from 85% to 92%.

Introduction to Epic Powder

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. It has been committed to the research and development of powder equipment for many years.

Main products include:

Powder grinding equipment: ball mill, jet mill, air classifier mill, etc.

Powder classification equipment: mainly including 5 types of air classifiers– HTS, ITC, CTC, MBS and TDC.

Powder modification equipment: pin-mill modification machine, three-rotor-mill modification machine, turbo-mill modification machine, etc.

Related auxiliary equipment: control cabinet, bag filter, suction fan, etc.

Our air classifier is developed under the guidance of our German consultants, with advanced technology, reliable quality, high classification accuracy, and has high reputation among customers.

If you are purchasing air classifier or other powder processing equipment, or need related technical advice, please contact Epic Powder. We will provide you with a full range of pre-sales, in-sales and after-sales services with professional technical support and reliable equipment quality, helping your powder processing to move towards higher standards and better markets.