Introduction

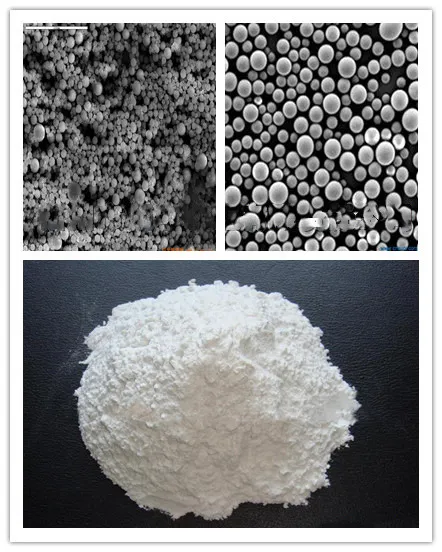

In the wave of modern industrial technology iteration, the collaborative innovation of materials science and equipment technology has become the core driving force for breaking through industrial bottlenecks. With its excellent insulation, thermal stability, and chemical inertness, spherical silica powder has become an indispensable key material in high-end fields such as electronic packaging, integrated circuits, and aerospace. However, the ultimate realization of its performance cannot be separated from the precise regulation of air classifier. This technology is like an “industrial sieve”, which can transform the potential of spherical silica powder into excellent performance in practical application scenarios through precise particle size classification and impurity control.

Starting from the diverse application of spherical silica powder, this article will analyze how air classifier can promote the value leap of this new material in the industrial chain through technological empowerment.

Multiple applications of spherical silica powder

1. Electronic packaging: the invisible guardian of thermal management

In the field of chip packaging, spherical silica powder, as a filler material for epoxy resin, needs to precisely match the thermal expansion coefficient of the chip. Air classifier can screen out particles of 1-10 microns, with a uniform distribution. This can ensure that the packaging material can not only efficiently conduct heat, reduce thermal stress, but also maintain stable mechanical strength, avoiding the problem of local stress concentration caused by uneven particles.

2. Copper clad laminate: the“stable channel”for high-frequency signals

5G communication has strict requirements on the dielectric properties of copper clad laminates. The spherical silica powder processed by air classifier can significantly reduce the dielectric loss of the material, and minimize the signal transmission delay. After the irregular particles are removed by air classifier, the spherical structure of the silica powder can be more easily and uniformly dispersed in the resin matrix. This can form a dense insulating layer, ensuring the integrity of high-frequency circuit signals.

3. Aerospace: The “Structural Code” for lightweighting

When spherical silica powder is added to aircraft composite materials, a balance needs to be struck between lightweighting and high-temperature resistance. The air classifier can classify particles of different sizes (e.g: particles of 5-20 microns are used to enhance strength, and particles of 1-5 microns are used to fill micro-holes). This can optimize the mechanical properties and thermal stability of composite materials, enabling them to withstand thermal shock and mechanical fatigue even in extreme environments.

4. Special coatings: the “optical magician” of surface engineering

In high-end optical coatings, the fineness and purity of spherical silica powder directly determine the light transmittance and abrasion resistance of the coating. The air classifier can separate ultra-fine powders in the submicron range, endowing the coating with better leveling properties. At the same time, it can avoid surface scattering caused by impurities, achieving an “invisible protection” similar to that of mobile phone glass coatings.

Collaborative innovation: from “single point breakthrough” to “ecological upgrading”

The collaboration between air classifier and spherical silica powder has gone beyond the simple relationship between “equipment – material” and it is moving towards a deep integration within the industrial chain.

✔Process closed loop: The classification data is fed back to silica powder production process (such as optimizing the preparation parameters of flame melting method), promoting the improvement of raw material quality from the source.

✔Scene expansion: Ultra-fine grading technology (such as 0.1 micron powder preparation) promotes the application of silicon powder in emerging fields, such as biomedical targeted drug delivery and quantum dot encapsulation;

✔Green transformation: The dust recovery system of air classifier can reprocess the tailings into building material fillers, increasing resource utilization from 80% to 99%.

Conclusion

Spherical silica powder demonstrates great application value in diverse fields due to its unique properties. The air classifier, through precise particle size control and performance optimization, serves as a crucial link in unleashing the potential of spherical silica powder. Looking ahead, with continuous innovation and breakthroughs in air classifier technology, spherical silica powder is bound to expand its application scope in more emerging fields. The deep integration of the two will inject a continuous stream of impetus into the vigorous development of the new materials industry and provide solid material and technical support for the innovative transformation of various industries.

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer specializing in powder processing equipment, with decades of production experience and technical expertise. Air classifier is one of our products, which is developed by our engineers under the guidance of German consultants. It includes 5 types: HTS, ITC, CTC, MBS and TDC. Over the years, they have received many good comments from customers.

Our products include:

Grinding equipment: Ball mill, jet mill, air classifier mill, roller mill, turbo mill, etc.

Classifying equipment: 5 types of air classifier– HTS, ITC, CTC, MBS and TDC.

Surface modification equipment: Pin-mill modifier, three-rotor-mill modifier and turbo-mill modifier, etc.

Auxiliary equipment: Control cabinet, bag filter, suction fan, etc.

Whether you want to purchase air classifiers or other powder processing equipment, or need technical advice, please contact Epic Powder. With professional technical support and reliable equipment quality, Epic powder will provide you with full range of services before, during and after sales, helping your powder processing to move towards higher standards and a better market.