Bentonite is a non-metallic mineral with montmorillonite as its main component, and it is a versatile clay material. Bentonite can be used in many industries, such as: foundry, construction and environmental engineering, which require precise particle size control to meet specific requirements. Classifying bentonite with air classifier has significant advantages over traditional mechanical separation methods. This article explores the main advantages of using an air classifier in bentonite classification.

1. Accurate particle size distribution

Air classifier utilizes advanced centrifugal force and air dynamics to achieve micron-level separation accuracy and narrow particle size distribution. This is critical for applications requiring controlled specific surface area, such as: drilling fluids or nano clay production.

2. High production efficiency

With the help of high-speed airflow, air classifier can quickly process a large amount of bentonite. Air classifier can realize continuous production, and it has a large processing capacity, which can meet the needs of large-scale industrial production. For some large bentonite processing companies, the use of air classifier can greatly increase the classification output.

3. Good product quality

Air classifier can effectively remove impurities and coarse particles in bentonite, making the bentonite uniform in particle size, high in purity and stable in quality. This can better meet the strict requirements of bentonite quality in different application fields, such as: high-end ceramics and cosmetics.

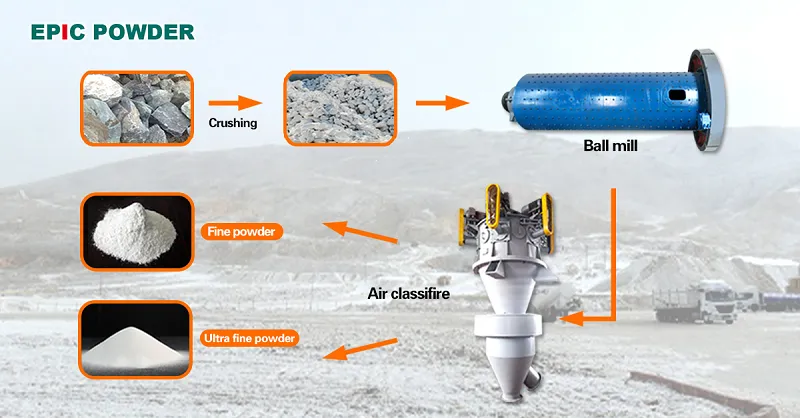

4. In series with grinding equipment

Air classifier can be connected in series with a variety of grinding equipment to form a circulation system. This can realize bentonite grinding and grading at the same time, which not only improving production efficiency, but also saving energy.

5. Low pollution and environmental protection

Air classifier usually adopts fully enclosed negative pressure operation to avoid dust spillage. This reduces the harm of bentonite dust to the production environment and the health of operators, meeting environmental protection requirements.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Air classifier is one of our products. It includes 5 types: HTS, ITC, CTC, TDC, and MBS, with different applicable materials and classifying effects.

OUR PRODUCTS INCLUDE:

– Mill: ball mill, roller mill, jet mill, turbo mill, etc.

– Air classifier: 5 types: HTS, ITC, CTC, TDC, MBS.

– Surface coating equipment: pin-mill modifier, three-rotor-mill modifier, turbo-mill modifier, etc.

– Auxiliary equipment: PLC cabinet, bag filter, bucket elevator, etc.

If you want to classify bentonite or other products with air classifier, please contact our staff directly, they will give you professional advice according to your specific situation. Choose EPIC POWDER, choose a more suitable air classifier.